What is Oxygen Index

EN ISO 4589-2 Oxygen Index Test - Standard Name

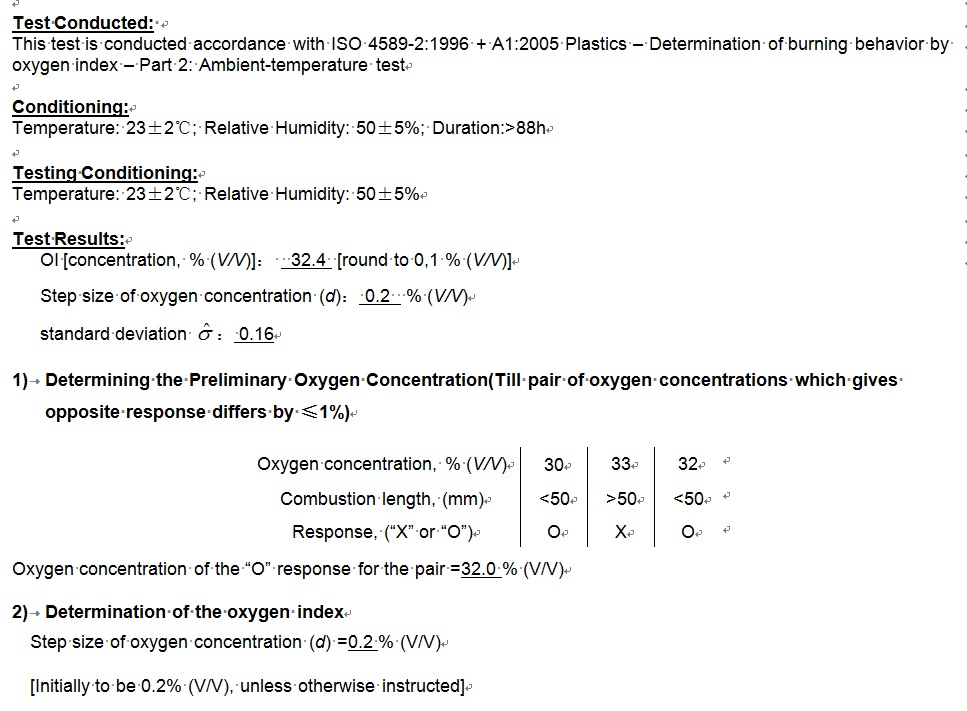

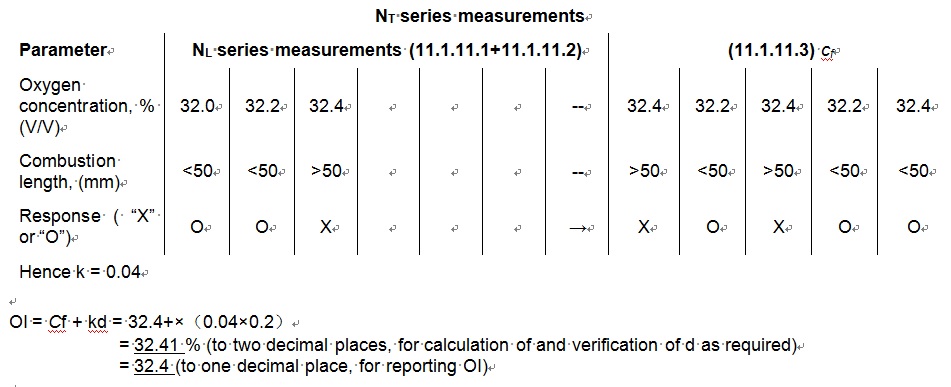

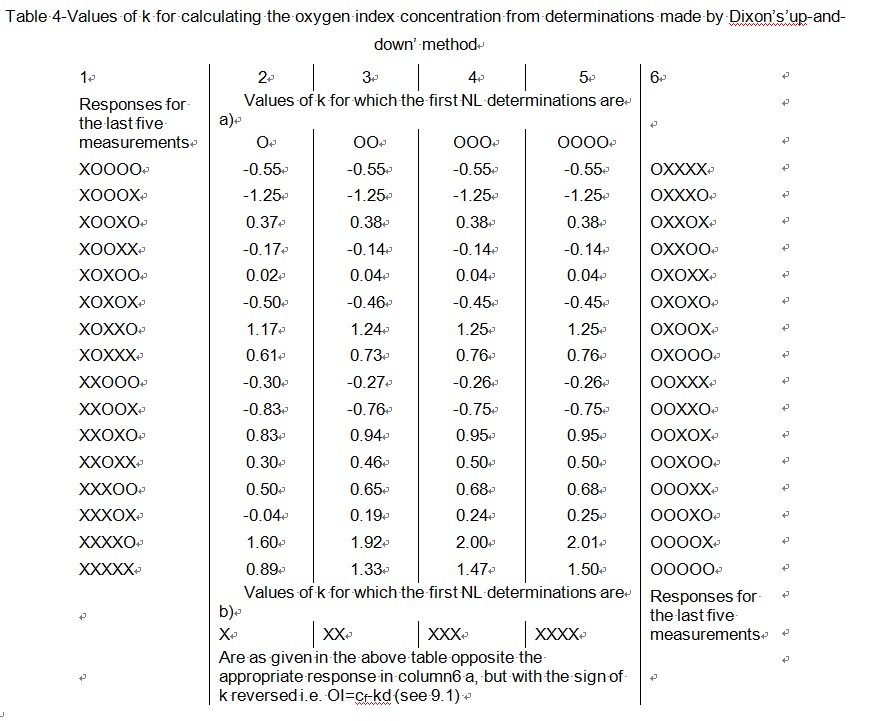

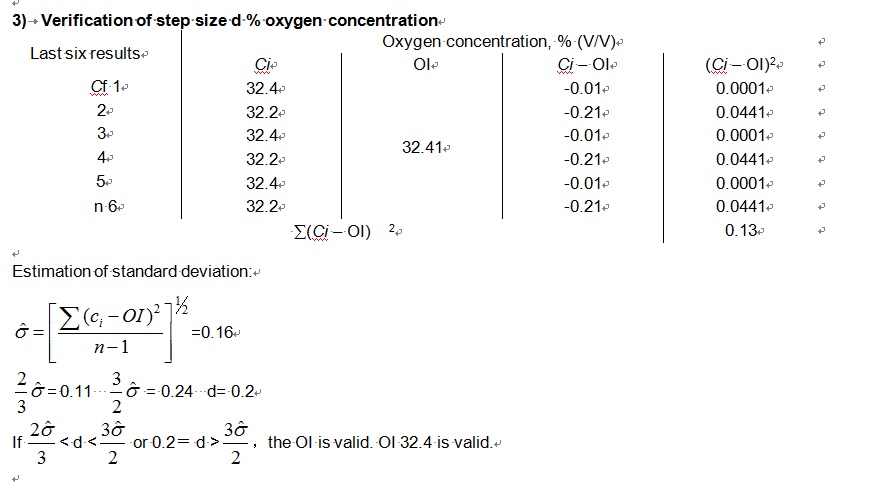

ISO 4589-2 Plastics - Determination of combustion behavior by oxygen index method - Part 2: Room temperature test

Oxygen Index Testing - Testing Principles

The test method involves introducing a mixture of oxygen and nitrogen at (23±2)℃ under specified test conditions to maintain the minimum oxygen concentration required for combustion.

Ignition method

Method A - Top surface ignition method, Method B - Diffusion ignition method

The top ignition method is designed for use with self-supporting materials such as moldings, foams, slabs, appliance moldings and sheets. At the beginning of the test, draw a mark 50 mm away from the ignition end. Every 5 seconds, the tester needs to remove the igniter until it is confirmed that the entire top surface of the sample is on fire. Once the top surface is on fire, remove the igniter and begin recording burn length. The contact time between the flame and the top surface of the specimen shall not exceed 30 seconds. If it does not ignite within 30 seconds, increase the oxygen concentration and continue trying to ignite.

The diffusion ignition method is applicable to non-self-supporting materials (such as films or films) as well as to self-supporting materials. This method involves the simultaneous application of a flame to the top and vertical surfaces of the specimen. During the ignition process, remove the igniter every 5 seconds or so until the vertical side surface is burning stably or the front edge of the visible burning part reaches the upper mark. After the flame was removed, combustion characteristics were evaluated. For film products, problems such as burning shrinkage may occur when using frame clamps. It is recommended to use the roll method to test to ensure the stability and reproducibility of the results.