Cone Calorimeter

According to

ISO 5660, BS 476-15,ASTM E1354, ASTM E1474; ASTM E1740; ASTM F1550; ASTM D6113; CAN ULC 135

The Cone Calorimeter measures the heat release rate of materials on the principle of oxygen consumption. The principle of oxygen consumption is that a material burns with roughly the same amount of heat for each unit of oxygen consumed. When the sample is exposed to the heat source of the conical heater, the conical calorimeter can measure the heat release rate, smoke generation rate, ignition time, oxygen consumption, carbon monoxide, carbon dioxide generation and mass loss rate of the sample.

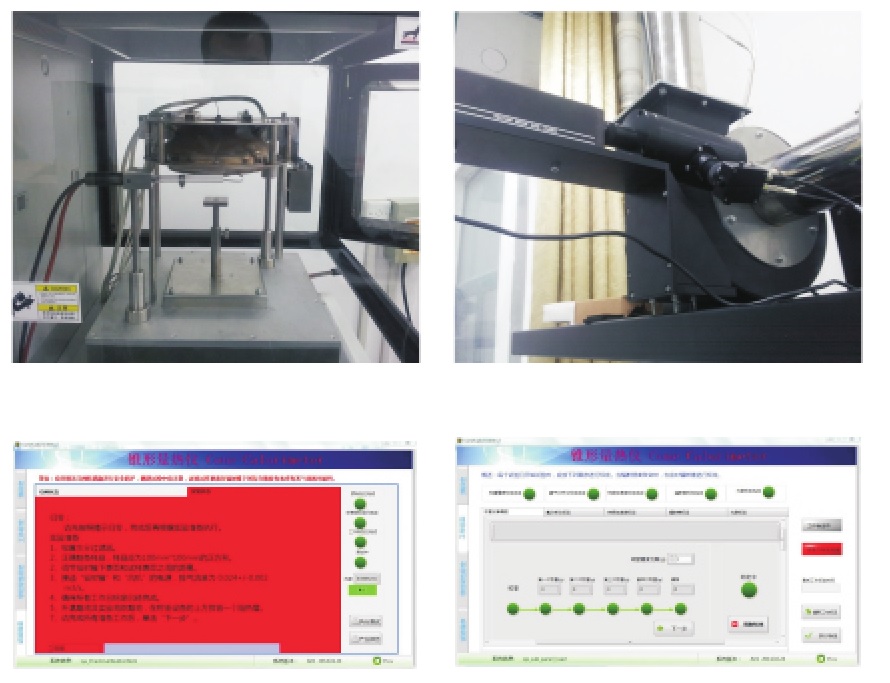

Cone Calorimeter consists of

The chamber body adopts combined frame structure, independent gas analysis cabinet and combustion test platform to reduce the influence of fan vibration on test data and ensure the stability and reliability of test results.

·The test bench area is installed with toughened glass observation window, used for observation and protection during the test, and explosion-proof steel net is installed at the bottom.

·The test platform adopts marble work table, high flatness, heat insulation, and beautiful and generous.

·Stainless steel radiant cone shell, heat insulation material filled between inner and outer cover. The temperature of heating wire is measured by k-shaped thermocouple, and the cone heat is adjusted by power regulator and temperature measuring module, with a power of 5KW. The radiation cone is well made and has a longer life, providing 0~100KW/ square radiation.

·Stainless steel test platform and sample box, can withstand radiant heat and sample burning high temperature, height adjustment device can be common sample and foaming sample test position adjustment.

·Equipped with standard calibration weights for weighing system calibration.

·The sample was ignited with a high voltage pulse spark plug and the ignition voltage was 10KV.

·Adopt brass calibrating burner, clip type installation mode, produce flame for calibrating hole plate coefficient C value.

·The calibration burner uses MFC to control the flow with a range of 10L/min, accuracy of ±1%F.S., linearity of ±0.5%F.S., and response time ≤2 SEC.

·Equipped with stainless steel smoke hood and exhaust pipe, meet the standard requirements.

·Adopting multi-wing centrifugal fan, equipped with frequency converter, the wind speed and flow rate can be adjusted stably.

·Thermothermopile heat flow meter and portable water cooling system allow real-time monitoring of cooling status on the panel. Automatic radiation cone heating power calibration is convenient and quick.

·Weighing device adopts Siemens weighing module, sensor range is 0-5000g, display precision is 0.01g .

·Equipped with standard filter for optical path system calibration.

·Brass ring sampler is installed in the equipment sampling pipe to collect test smoke. The sampling hole is away from the wind speed flow direction to prevent the blockage of combustion dust.

·The sampling probe is connected to the sampling pump through the PP hose to pump the sampling gas to the gas pretreatment system. The sampling pump pumping volume is 36L/Min, working pressure 7 Kg air pressure (0.7mpa) working vacuum degree -93.1kpa, flow rate (50Hz) 36L/Min.

·The gas pretreatment system includes filtration system, gas cooling system, gas dehumidification and drying system and gas regulation system.

·Equipped with a three-level filtration system, the first level of filtration is the cylinder coarse filtration system, used to filter the relatively large particles in the flue gas, prevent the blockage of pipes and joints, the filter can be replaced. The secondary filter adopts cup type protective filter to filter particles larger than 0.5μm in size. The filter element device can be replaced. The three-stage filter adopts membrane filter to filter particles larger than 0.2μm.

·The cooling system is condensed and dehydrated by condenser and peristaltic pump. The condenser has dual cooling, the stable dew point temperature is about 0.1℃, the outlet temperature is about 5℃. The outlet of peristaltic pump is equipped with condensate collecting box with built-in sponge.

·The dehumidification and drying system uses the air filter tube to place DRIERITE brand anhydrous calcium sulfate for dewatering treatment, and filters the gas moisture to be measured in the air pipe to ensure the drying of the gas entering the analyzer. Anhydrous calcium sulfate can change color after absorbing water, easy observation and easy replacement.

· Equipped with imported thermocouple to monitor the temperature in the exhaust pipe, the measurement accuracy is ±0.1℃

·Thermocouple and pipe sleeve connection, convenient disassembly and processing.

·Equipped with orifice plate differential pressure structure to measure wind pressure, pressure tube is located on both sides of orifice plate.

·Equipped with imported differential pressure transmitter to convert pressure signal and output.

·Equipped with imported laser transmitter and silicon light receiver for measuring the change of smoke concentration in the smoke tube.

·Analysis/calibration switch unit: analyze the cabinet panel has sample gas inlet, standard gas inlet quick plug, and adopts high reliability ball valve, three-way switch valve, easy to field adjustment and maintenance.

·Fast bypass: It is equipped with Devere rotor flowmeter for sample gas bypass discharge. The flowmeter is mounted on a panel to ensure that the sample gas flow into the analyzer is 3.5L/Min.

·Pressure regulating device: the pressure regulating valve is used to adjust the pressure, and the pressure of the regulating valve can be adjusted from 0 to 0.4mpa.

·Professional HRR test gas analyzer, including O₂, CO₂:

·O₂ : paramagnetic sensor, range 0-25%, accuracy 0.02%, response time T90< 7s.

·CO₂ : infrared sensor, range 0-10%, accuracy 1%F.s, response time T90< 8S.

·Support analog output and Modbus RTU and other transmission modes.

·Test data by conical calorimeter combustible materials in the fire combustion parameters have a variety of, including heat release rate (HRR), total release heat (THR), effective combustion heat (EHC), lighting time (TTI), mass loss rate (MLR), smoke generation rate (SPR), total smoke volume, CO₂/CO generationThe built-in calibration system can calibrate the equipment according to various standards.

If you have a particular need for fire test instruments or are just in the planning stage, let's contact us.·