BS 476 Part 7 Surface Spread of Flame Test

According to

BS 476 Part 7

BS 476-7 test method is a method for determining flame propagation properties of materials by exposing specimens to specified convective conditions in accordance with the standard requirements and determining transverse flame propagation on vertically placed specimen surfaces.

Can be used to compare the final performance of flat materials, composite materials and components of walls or ceilings.

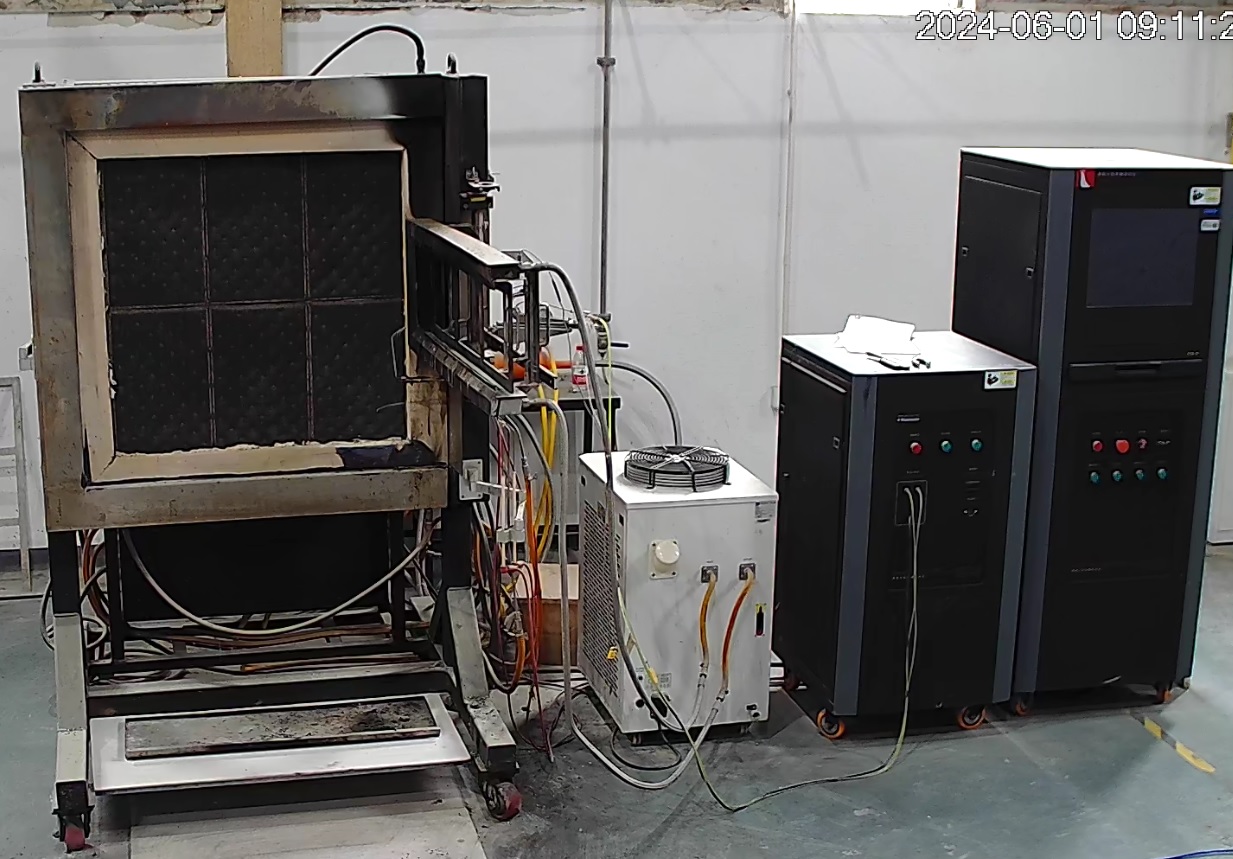

The product realizes the ignition function of radiation plate through small ignition flame, and adjusts the gas flow to reach the standard radiation flux. The radiation plate covers an area of 850mm×850mm, and is equipped with a gas cooling frame around it. The test sample frame adopts water cooling mode, and is equipped with a radiant heat flux calibration plate to achieve porous calibration.

BS 476 Part 7 Surface Spread of Flame Test consists of

· Carbon steel test bracket, stable structure, to ensure the load bearing and safety of equipment.

· The independent distribution chamber is located on the backfire surface of the radiant plate, which can supply air to the radiant plate quickly and ensure safety.

· Independent control cabinet away from heat source, reduce radiation heat damage to equipment, improve equipment life, convenient operation.

· The size of radiant plate is 850mm*850mm. The radiant plate is equipped with cement frame and air-cooled stainless steel frame around it.

· A precision mass flowmeter supplies gas and combustion air to the radiant plate. The inlet pressure is regulated by brand pressure gauge and pressure regulating valve, and the imported Venturi mixed air-fuel ratio makes the gas fully burned.

· Equipped with flame control device to control the flame of radiation plate, abnormal flameout control and early warning, to ensure the safety of the test.

· The specimen support adopts mechanical rotating device, which can be quickly positioned in the test position.

· The sample frame is equipped with a chiller circulation device to ensure that the sample can run in a high radiation flux environment for a long time.

· The sample ignition is equipped with a small igniter, which is ignited by electric spark ignition. During the test, after the radiation plate is placed in place, the small igniter will be timed automatically, and the gas output will be automatically shut down after 60 seconds.

· The gas is divided into multi-channel input radiation plate to ensure the stability of radiation flame. The gas circuit is equipped with pressure regulation and anti-backfire device, and the radiation plate is equipped with multi-channel gas flow regulation device to ensure the safety and stability of the test

· Radiating panel ignition adopts small fire ignition mode, equipped with electric spark ignition device, ignition is stable and reliable.

· Ignition of radiant plate adopts ignition source, ignition source is adjusted by the inlet rotor flowmeter, and automatic ignition by high pressure pulse, ignition is stable, safe and reliable.

· Imported thermoelectric reactor heat flow meter, 0-100kW/m², accuracy ±3%, repeatability ±0.5%. Equipped with portable water cooling system, with its own circulating water and water cooling device, without external cooling water source. Water temperature and water flow condition can be displayed on the panel for real-time monitoring of cooling status.

· Equipped with standard porous calibration plate, which can be used for radiation flux calibration at each point of the radiation plate.

· Electrical control adopts self-designed electrical cabinet, built-in integrated touch computer, with Siemens control module to achieve function control and data collection.

· The upper computer software is designed based on NI Labview platform, which can realize data recording, calibration report and test report output view and other functions.

If you have a particular need for fire test instruments or are just in the planning stage, let's contact us.